This means that for every sale of an item you’re getting a 90% return with 10% going toward variable costs. Variable costs earn the name because they can increase and decrease as you make more or less of your product. The more units you sell, the more money you’ll make, but some of this money will need to pay for the production of more units. Tapping into renewable energy resources like solar or tidal power wherever feasible can also help reduce electricity consumption costs.

Variable Costs: Definition and Examples

Direct costs for manufacturing an automobile, for example, would be materials like plastic and metal, as well as workers’ salaries. Indirect costs would include overhead such as rent and utility expenses. Total product costs can be determined by adding together the total direct materials and labor costs, as well as the total manufacturing overhead costs. To determine the product cost per unit of product, divide this sum by the number of units manufactured in the period covered by those costs. When we compute unit product cost, the difference between variable costing and absorption costing is that fixed overhead is not included in the product costs for variable costing.

Identifying Core Cost Components

They are exactly the opposite of fixed costs that do not change due to changes in production. Knowing your unit product cost is crucial for pricing products profitably, managing inventory efficiently, and accurately assessing overall business performance. Without this knowledge, it’s difficult to set prices that ensure you’re covering your costs and making a profit. As a general rule, the difference in net income under absorption costing and variable costing is due to the change in inventories. On the other hand, if inventories decreased, then that means sales exceeded production, and income will be larger under variable costing than under absorption costing.

- It’s a crucial key performance indicator (KPI) because it directly impacts your bottom line.

- This fixed cost portion is transferred to each unit and then calculated to the cost per unit so that there is a proper recognition of these costs.

- You can also consider implementing lean principles to achieve inventory optimization and minimize waste due to excess inventory, poor workflows, or long wait times.

- For professionals dealing with operations management, production, or pricing, knowing how to calculate the cost per unit can be highly beneficial.

Tools of the Trade: Software and Systems for Unit Cost Management

Once gross profit is calculated, selling and administrative costs are subtracted to determine the income. Calculating the unit product cost is an essential part of manufacturing and product pricing. This calculator helps businesses determine the cost of producing a single unit of a product by considering direct materials, direct labor, and overhead costs. By understanding how much it costs to produce each unit, companies can set competitive prices, manage their budgets, and optimize their profit margins. In this article, we’ll explore how the unit product cost calculator works, how to use it, and provide examples to help you better understand this essential calculation.

What is the difference between total cost per unit and quantity sold methods?

Meredith Flora is a Food Truck Accounting Content Marketing Manager at ShipBob specializing in supply chain management, logistics, and ecommerce fulfillment. She holds a BA in Communications and Public Relations from Virginia Tech, and brings 4+ years of expertise in supply chain content marketing. Meredith has authored 200+ blog posts, 20+ merchant case studies, and 10+ eBooks for ShipBob. She has also written content for Arka, Adquadrant, Okendo, and Tydo, establishing herself as a thought leader in logistics and fulfillment strategy. Instead of having to handle all SKU management and logistics on your own, you can outsource it to ShipBob and save time, energy, and money. “Overall, there is more transparency with ShipBob that even helps our team manage customer service better.

Also, you will have one manager and one quality-control technician present to oversee the work. Direct materials are the raw components and materials directly used in the production of a product. Tracking labor hours per unit and optimizing production processes can lead to significant cost savings. Direct labor encompasses the wages and benefits paid to employees directly involved in the manufacturing process.

How Variable Costs Work

Fixed costs are those that remain constant regardless of your production volume, at least within a certain relevant range. These are the expenses you have to pay whether you how to find unit product cost produce one unit or one thousand. While unit cost is a critical component, it’s important to understand that it’s part of a larger discipline called cost accounting. Cost accounting involves identifying, measuring, analyzing, interpreting, and communicating cost information to management for the pursuit of the organization’s goals. We understand that you may not have a dedicated accounting team, and that’s perfectly okay.

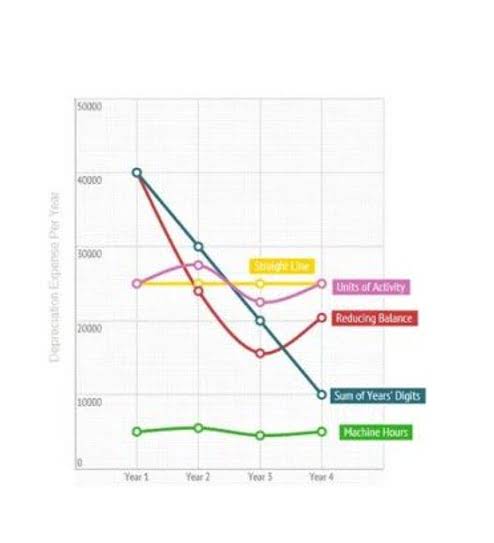

Using software to calculate your product’s unit cost

Fixed overhead costs are constant and do not change with the level of production. Overhead costs, both fixed and variable, are included in the absorption costing method to allocate a share of these costs to each unit produced, impacting the total cost per unit. In this article, we will explore the concept of absorption costing, explain how to use an Absorption Cost Calculator, and provide a detailed example. We’ll also dive into how absorption costing benefits your business, helping you price products accurately and manage production costs effectively. Additionally, we’ll answer 20 frequently asked questions (FAQs) to further https://astoundinnovation.com/bond-premium-amortization-how-it-affects-your/ clarify any doubts you might have. Understanding the unit product cost is crucial for any business involved in manufacturing or selling products.

- It is the contrary scenario from fixed costs where, those costs would be incurred irrespective of the output of the organization.

- Therefore, the cost to produce one unit of their very large dog food in February 2022 was $80.

- Scenario analysis helps assess the impact of changes in variables like input prices, production volumes, and market demand on the cost of a unit.

- Initially, the average cost tends to decline as more units are produced—i.e.

Has the business of manufacturing and selling readymade garments in the market. Direct labor refers to wages paid to employees who directly transform raw materials into finished goods. This includes compensation for workers who assemble products, operate machinery, or directly sew garments. Their time and effort are directly attributable to each unit’s creation.

Providing financial data inside the company to managers, owners, and employees. Keep in mind that the items above should be “consumable materials” only – these are materials that are completely used up during the creation of your product. The best way to illustrate how to calculate your unit price is with an example. Our advanced tool enables you to efficiently prioritize delivery stops, manage multiple routes, and ultimately save valuable time and fuel expenses. By adopting effective customer management practices, you can ensure timely order fulfillment and enhance customer satisfaction with their purchases. Ensuring packages are delivered in excellent condition is essential for customer satisfaction.

Leave a Reply